Black Moda Oy offers textile brands high-quality, OEKO-TEX® certified production in Portugal – flexibly and transparently. Designing a collection for production takes time and collaboration. In this post, we’ll briefly explain how to design your products and collections so that they are produced in Black Moda’s production efficiently, responsibly, and exactly as you envisioned.

1. Start designing early – responsibility takes time

A high-quality collection rarely comes together in a rush. We recommend starting product development with Black Moda about a year before your planned launch.

An early start gives you enough time for material testing, prototypes, pattern finalization, and feedback rounds – all the stages that ensure a successful and responsible end result.

2. Choose suitable and certified materials

Black Moda Portugal, Lda manufactures both jersey and woven products. The material selection includes, among others, cotton, viscose, modal, linen, and lyocell – all OEKO-TEX® certified. You can also choose organic cotton or Lenzing™ Ecovero™ viscose for your collection.

Ethical European production ensures that the products are safe for both the wearer and the maker.

If you want your products to carry the OEKO-TEX® label, mention this already at the ordering stage and in the product sheets.

💡 Tip for designers: If you’re developing a new knit quality, allow time for development and make a backup plan using an existing option – the first structure doesn’t always work perfectly.

3. Know the production minimums and plan realistically

The usual sewing minimum for jersey products is 300 pieces per product and color, but the final quantity is always confirmed on a case-by-case basis. Knitted fabrics have their own minimums – for example, 60 kg for solid-colored fabrics and 100 kg for striped ones.

In some product categories, smaller batches may be possible, but cost efficiency improves significantly when these minimum quantities are taken into account from the very beginning of the design process.

4. Create detailed product sheets and measurement charts

Thorough planning is the foundation of everything.

At the early stages of product development, please provide us with product sheets and measurement charts that include product images, materials, color codes, sewing constructions, labels, and packaging details.

We recommend using PowerPoint or Excel files – this way, we can add our comments directly into the same documents. If needed, we can also provide you with a ready-made PowerPoint product sheet template.

Clear instructions help ensure that production proceeds without delays and that the final product matches your vision. A measurement tolerance of ±1 cm is allowed in production, so accuracy and realism in measurements are essential.

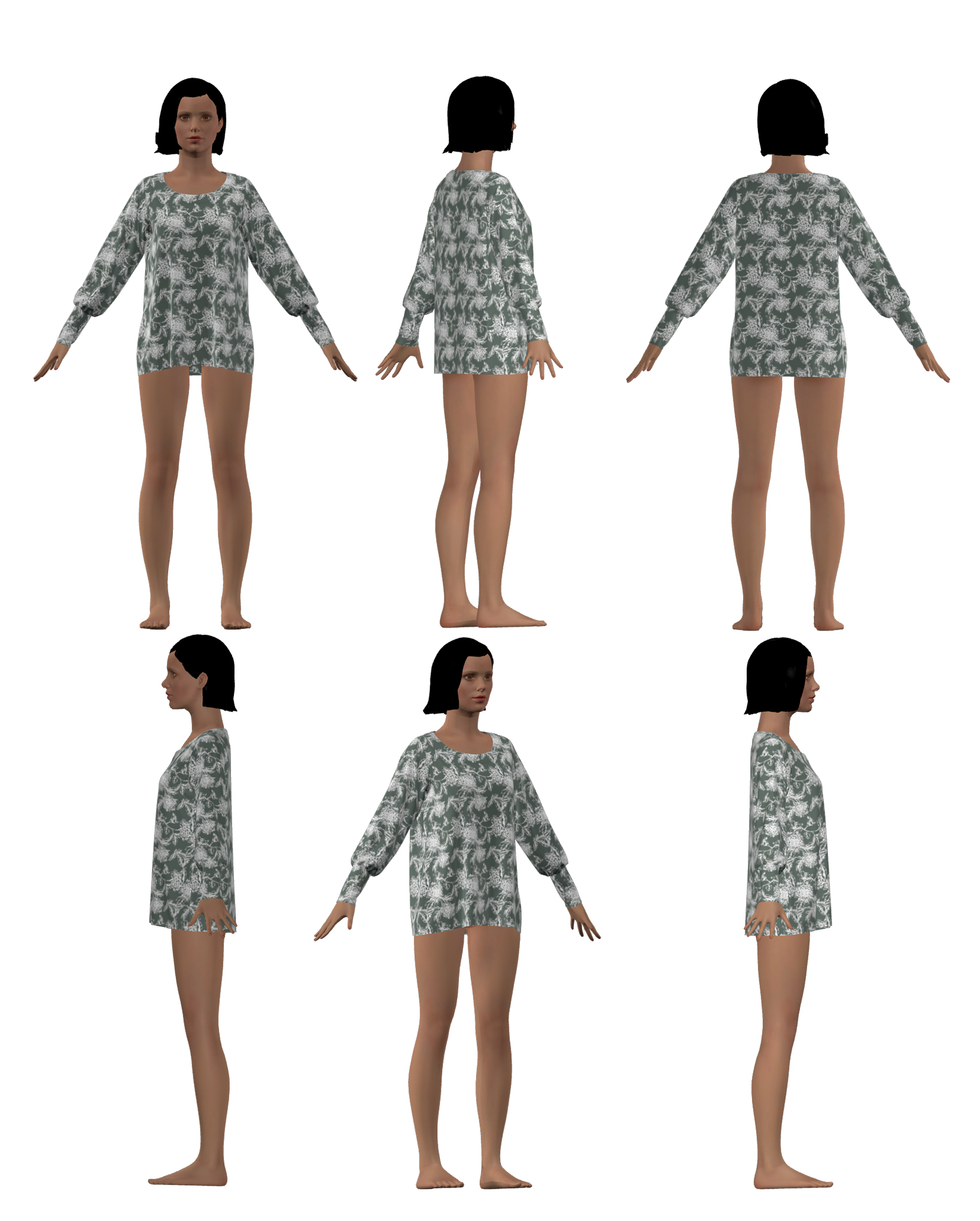

5. Make use of prototypes and 3D pattern making

New products should be tested with a prototype. Black Moda also offers 3D pattern making, which allows you to examine fit, drape, and prints virtually before producing a physical sample.

This saves shipping costs and reduces the carbon footprint – responsible and cost-efficient product development at its best.

6. Design the printing technique as part of the whole

Black Moda specializes in rotary and digital printing techniques that ensure a high-quality and durable result.

Rotary printing is ideal for large batches and repeating patterns, while digital printing allows for multicolored and detailed prints.

💡 Waste reduction tip: Design your print so it can be cut in two directions – this reduces material waste and lowers the product’s cost.

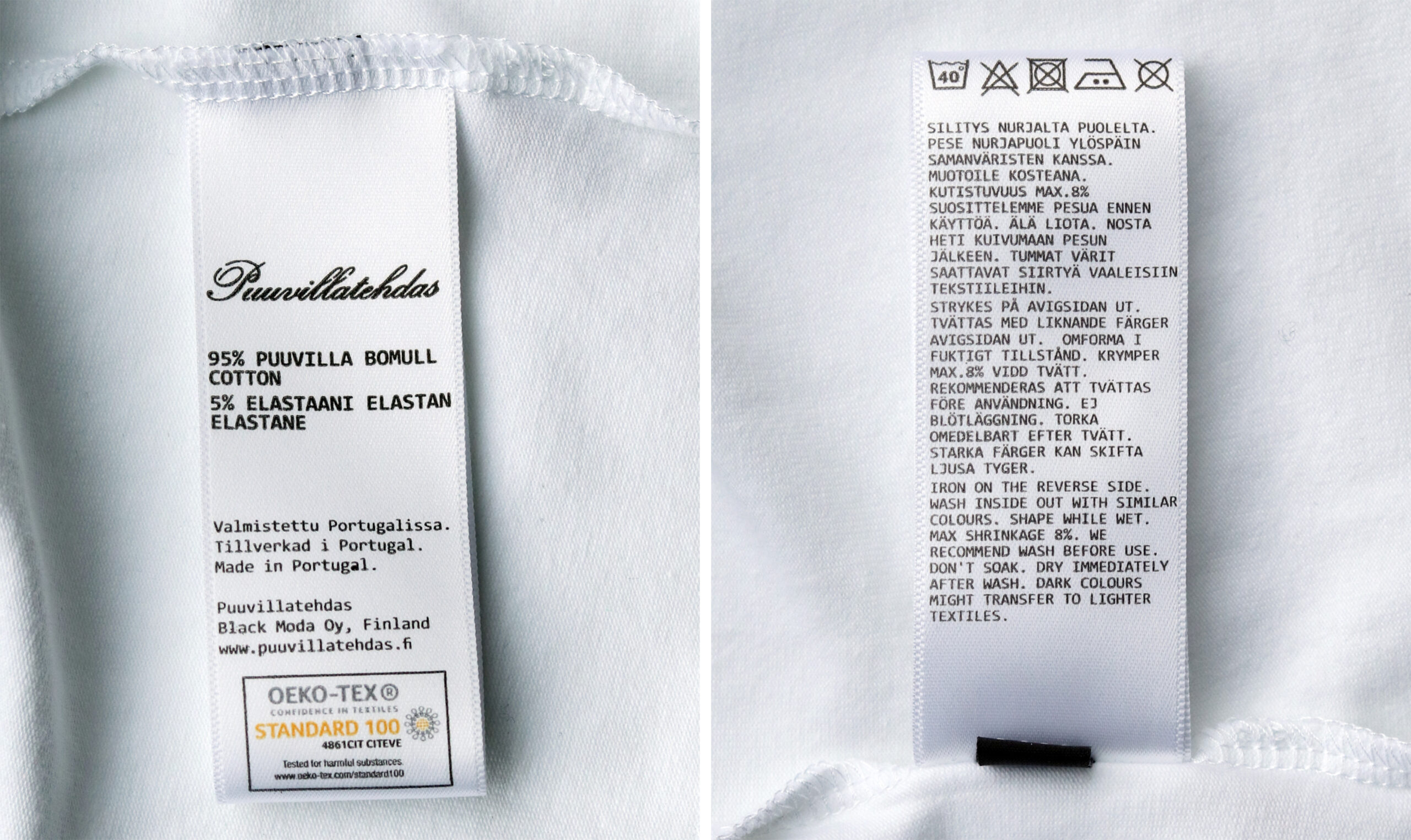

7. Ensure labeling and responsibility

All Black Moda products are manufactured in compliance with EU working conditions and regulations.

Whenever possible, products can include the OEKO-TEX® label, which indicates that they are free from harmful substances and safe to use.

Remember that every product must include the following mandatory labels:

- Fiber content (official fiber names)

- Manufacturer’s or importer’s name

- Care instructions in Finnish and Swedish (and in English if the product is sold outside Finland)

- Country of origin (if required)

A production batch code is automatically added to every product we manufacture.

In Conclusion: Responsible Clothing Production Is a Collaboration

Working with Black Moda is, above all, a partnership that combines responsible production, family entrepreneurship, and professional expertise.

Designing a collection for production is a key part of creating a responsible line. When design is done carefully and schedules are realistic, the result is products that stand the test of time — both in quality and in values.

📩 Interested in production at Black Moda Portugal Lda? Click here and get in touch with our experts.