Sustainability

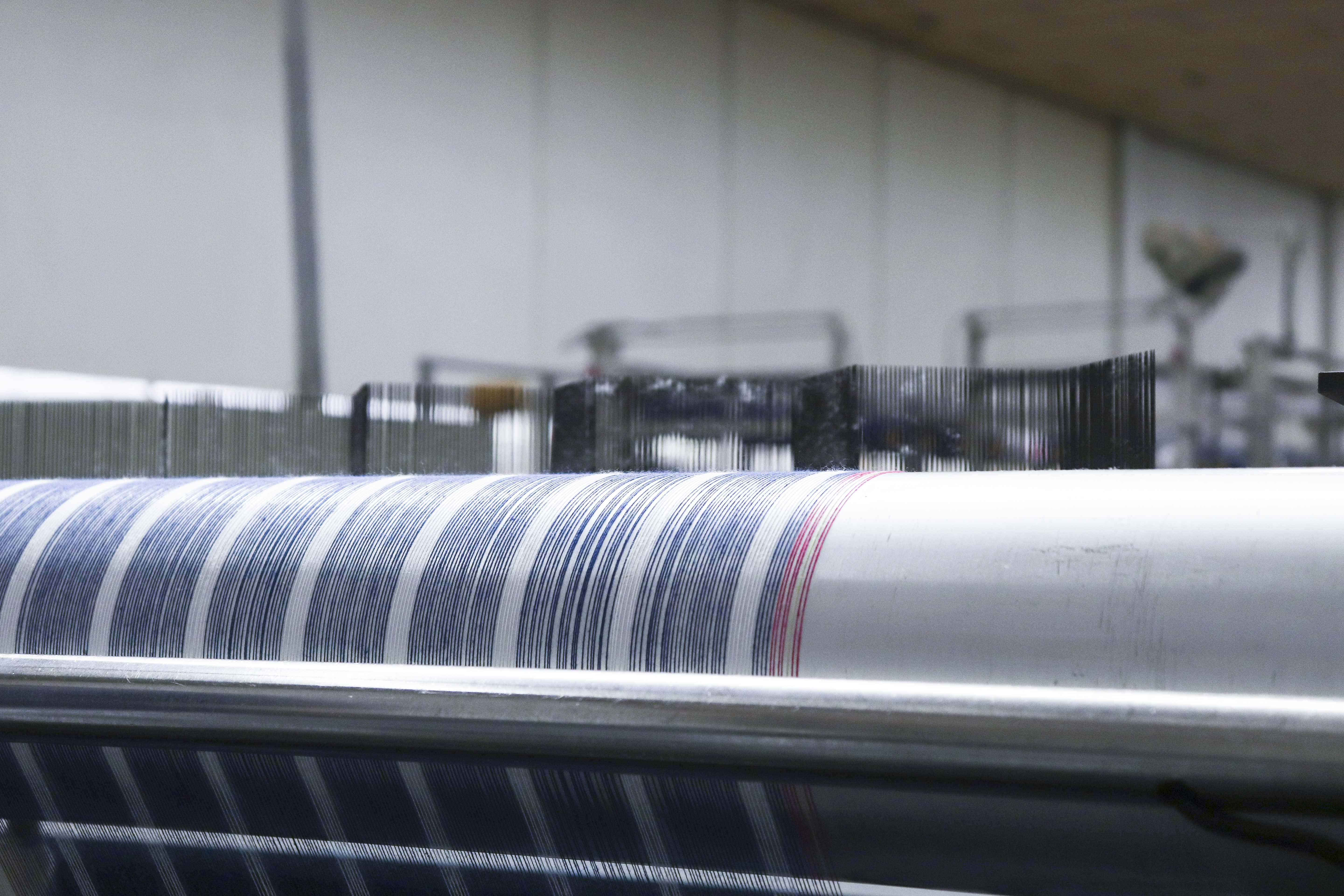

The textile and clothing industry are changing.

Consumers are increasingly aware of the downside of the industry, human rights violations and the environmental burden of this industry. The choices you make are thought-provoking, and finding out the origin of a T-shirt, for example, may prove impossible in practice. Fast fashion is so last season. Therefore, the appreciation of clothing and people working in the industry must increase. That’s why we want to tell you more about our production, our responsibility and the working conditions of our employees. Responsibility cannot be mere talk and fine words, but real deeds.

Our annual Sustainability Report aims to improve the understanding of our operations and our work towards a more responsible textile production for our production customers, consumers and partners, as well as our stakeholders. When reporting, we report the challenges, successes, and failures that have been identified in our work. Sustainability and how to practice it, is something we constantly discuss in our daily work.

Our corporate responsibility consists of financially a responsible governance, a healthy corporate culture and employee well-being, our own sewing company, partners and materials.

The figures here in our Sustainability section are only a small part of what we have covered in our report. In our Corporate Responsibility Report, we will tell you more about our goals for the coming years and open up more figures behind our production. If you are interested and want to read more about our corporate responsibility, read the full report.

Own Factory Black Moda Portugal

Black Moda Portugal is a family owned company in Portugal owned by siblings Riikka Oliveira and Marko Keski-Vähälä. Own production creates the basis for quick response and flexible operation between customer service and production itself.

Portugal is an EU country that is not classified as a risk country.

In Portugal, working life is regulated by law and the authorities also enforce these laws. Portugal has ratified the International Labor Organization (ILO) Treaties. In accordance with the principles of the ILO, all its Member States have a duty to eliminate forced labor, child labor and discrimination and to guarantee freedom of association.

Black Moda Portugal is a member of the Portuguese textile industry association, ANIVEC. All employment contracts are based on a collective agreement. Our company pays collective wages to employees that are higher than the minimum wage set by the State.

Below you will find the data for 2021.

ECONOMIC INDICATORS

710 981

Produced Quantities

€ 841 872

Paid Salaries

€ 2 968 925

Turnover

STAFF

The training is related to, among other things, communication and customer service, industrial occupational risk prevention, studying English and transport documents.

1 satisfaction enquiry.

2 work related accidents.

ENVIRONMENTAL IMPACT

92 422 KWh

Electricity

59 051 kg

Textile Waste

58,6 tons

CO2

Together, Black Moda Oy and Black Moda Portugal employ 86 people.

All employees at Black Moda Portugal receive a 10 € / month punctuality allowance, holiday pay and food supplements. In addition, seamstresses receive an incentive supplement of up to € 60 per month.

Portugal has a law on working time.

Our own sewing company complies with the obligations of the Portuguese authorities regarding working time laws, holidays and maternity and parental leave. Possible overtime is agreed with the employee and overtime compensation is paid.

For more chapters, goals and information about our sewing company, read our report.

Partners in Portugal

Most of our partners are based in Portugal.

This is also reflected in the billing as 95,3 % of the orders paid by Black Moda Oy are made in Portugal.

The supplier contracts made with our partners are accompanied by a Code of Conduct (CoC), ethical principles and state that the supplier must manufacture products in compliance with the REACH Chemicals Regulation.

We value long term supplier relationships. Thus, we believe trust and fruitful cooperation between suppliers are valuable assets today.

Our own sewing company and partners have their doors open, and our production customers are welcome to familiarize themselves with the operation and working conditions of our sewing company and partners anytime.

THE START YEAR OF PARTNER RELATIONSHIP

Materials and Raw Materials

The use of high quality and certified materials in production is the key to a high quality end product that is economically, ecologically and emotionally viable investment.

Organic cotton is our most used raw material. These means it has been grown without harmful fertilizers and pesticides.

The standard limits the use of certain textile chemicals that are considered harmful. Certification by independent research institutes guarantees that the product is free of harmful pesticide, heavy metal or formaldehyde residues.

GOTS defines high environmental criteria, covering the entire organic textile production chain from the field to the finished product, and requires compliance with social criteria.

The Better Cotton Initiative (BCI) is a global non-profit organization and the largest cotton sustainability program in the world. BCI’s mission is to make global cotton production better for the people who produce it, the environment in which it grows, and a better future for the industry.

The textile and clothing sector has come to the point where it is necessary to find substitute materials for cotton and recycling processes for textile waste. Cultivation of cotton requires a lot of water, fertilizers and pesticides. At Black Moda, we invest time in finding new solutions for our production. You can read more about our efforts in the full report.